When users begin the search for a high quality air compressor, they quickly realize there are many technical considerations that can influence performance, durability, and suitability for specific applications. Whether you are evaluating options from compressor China manufacturers or sourcing units locally, understanding core technology differences makes your purchase more confident and better aligned with real needs.

1. Different Compression Technologies Explained

Air compressors come in several different forms, each built around a specific method of compressing air. The more common technologies users encounter include:

Piston (Reciprocating) Compressors: These use a piston driven by a crankshaft to compress air in a cylinder. They are often used for intermittent duty applications such as light workshop tasks or pneumatic tools.

Rotary Screw Compressors: These units employ twin helical screws that compress air as they turn. They’re frequently used in industrial settings for continuous duty because they produce a steady air flow and tend to run cooler.

Scroll and Centrifugal Compressors: Scroll compressors are quieter and more compact, while centrifugal compressors are often used for large volume, high‑flow industrial needs.

Each method has strengths and trade‑offs, and matching the technology to your intended use ensures a better long‑term experience. For example, rotary screw technology often supports longer duty cycles with lower vibration, which can be preferable in manufacturing environments.

2. Duty Cycle and Operating Expectations

A crucial concept that many users ask about is duty cycle — that is, how long a compressor can run before needing rest. Different technologies have inherently different duty cycles:

100% Duty Cycle Machines: These compressors, frequently screw models, are designed to run continuously without forced rest periods.

Intermittent Duty Machines: Common for smaller piston compressors, these units require cooling periods to avoid overheating.

If your application requires consistent air delivery, especially for industrial tasks, selecting a compressor with an appropriately rated duty cycle is essential to avoid premature wear or shutdowns.

3. Power Source and Electrical Compatibility

Another important decision users face is power supply compatibility:

Single‑Phase Power: Common in residential or small workshop settings.

Three‑Phase Power: Typically found in industrial facilities, providing smoother power delivery for heavy loads.

Matching your facility’s electrical infrastructure to the compressor’s power needs avoids complications such as needing external phase converters or costly rewiring. This alignment also ensures the machine runs efficiently and safely over time.

4. Oil‑Free vs Oil‑Lubricated Systems

Users often ask about the difference between oil‑free and oil‑lubricated compressors because this affects maintenance, air quality, and application suitability:

Oil‑Free Compressors: Produce cleaner air with fewer contaminants — ideal for medical, food processing, or laboratory environments.

Oil‑Lubricated Compressors: Generally more durable under heavy loads and provide better cooling and lubrication in continuous industrial use.

Understanding your air quality requirements helps you select the appropriate system while balancing maintenance needs and costs.

5. Maintenance and Overall Lifecycle Requirements

Users frequently ask how to plan for maintenance and total lifecycle costs when choosing a compressor. Key questions include:

How often do filters, belts, and lubrication need replacement?

Are spare parts readily available, and how quickly can they be delivered?

Does the manufacturer provide clear service guidance?

These concerns are especially relevant when considering units from compressor China manufacturers, where access to parts and support can vary. Aligning service expectations ahead of time reduces downtime and unexpected maintenance costs.

Supporting your maintenance plan with regular inspections, filter servicing, and documented routines is important for many users. For instance, ensuring correct oil levels, promptly detecting leaks, and scheduling periodic full system checks significantly reduces the risk of unexpected shutdowns.

Making a More Informed Compressor Selection

Choosing a high quality air compressor is not a one‑size‑fits‑all decision. Users must assess their specific application needs, duty cycles, technology types, power compatibility, and maintenance expectations. When you take these factors into account, your purchase aligns more closely with actual performance requirements rather than guesswork or marketing claims.

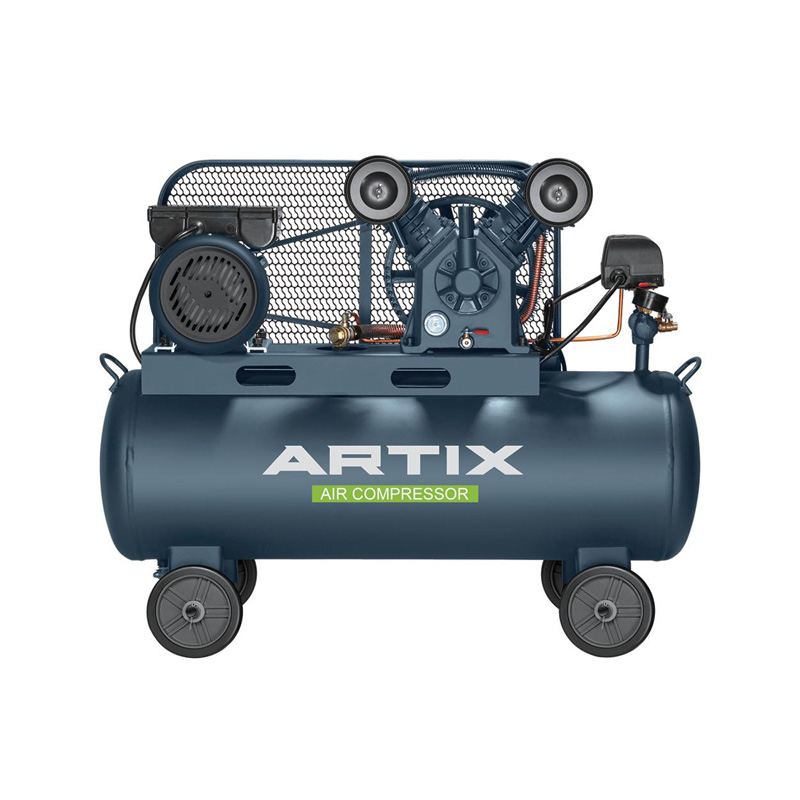

For businesses seeking dependable performance and robust support, companies like Artix Machinery Co., Ltd. emphasize both product reliability and detailed technical guidance to help customers make informed choices.