Oil-free compressors are a smart investment for businesses looking to improve operational efficiency, reduce environmental impact, and ensure the highest air quality. With their lower maintenance costs, energy efficiency, and reliability, oil-free compressors offer long-term value for industries across the board. As oil free compressor manufacturers, we understand the technology behind these devices and how they function.

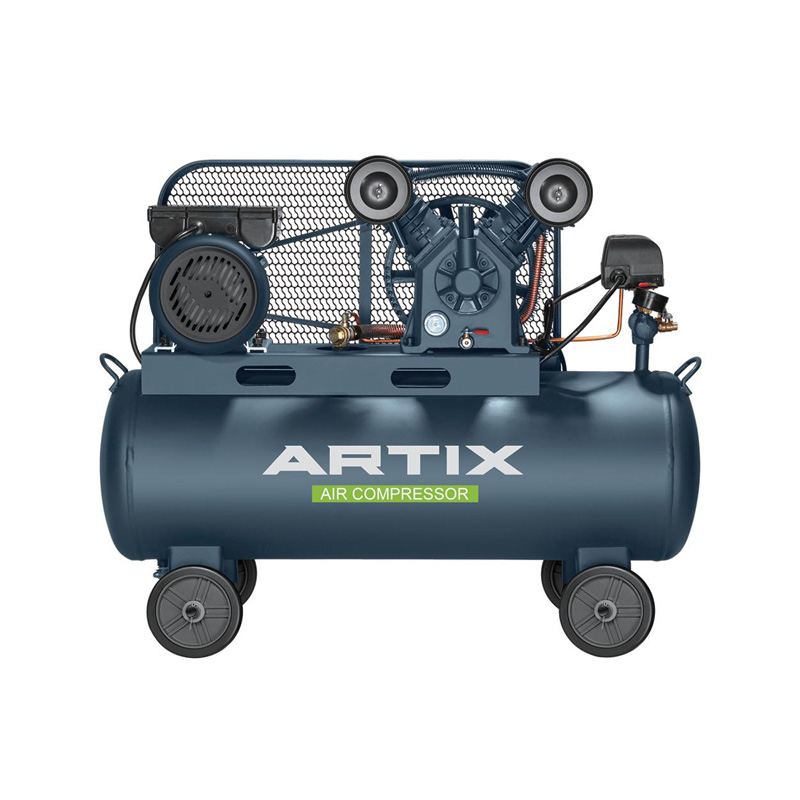

At Artix Machinery Co., Ltd., we are dedicated to providing oil-free air compressors, including oil free screw compressors, that meet the demands of modern industry.

Key Benefits of Oil-Free Compressors

Lower Long-Term Operating Costs

One of the more significant advantages of oil-free compressors is their ability to reduce operating costs over time. Traditional compressors require oil to lubricate moving parts, resulting in ongoing maintenance costs such as oil changes, filter replacements, and oil disposal. Oil-free compressors, on the other hand, do not require oil, significantly reducing these expenses. This lower maintenance requirement translates to savings on service costs and reduced downtime, making oil-free compressors a cost-effective option in the long run.

Reduced Environmental Impact

Oil-free compressors are environmentally friendly, contributing to sustainability efforts in the industrial sector. Without the need for oil, there is no risk of oil leaks or contamination, which can cause significant environmental damage. Additionally, since oil-free compressors do not require oil disposal, they help reduce waste and pollution, aligning with green practices that many businesses are increasingly prioritizing.

For industries focused on minimizing their carbon footprint and adhering to environmental regulations, oil-free compressors provide an ideal solution. The reduction in waste and the avoidance of oil-based contaminants ensure that these compressors contribute to a cleaner, greener environment.

Enhanced Reliability and Durability

Oil-free compressors are designed for reliable, long-term performance. By eliminating the need for oil, these compressors reduce the wear and tear that typically occurs due to the lubrication process in traditional compressors. Oil-free screw compressors, in particular, are built with precision-engineered components that ensure smooth operation, even under demanding conditions.

The absence of oil also reduces the likelihood of oil contamination in the compressed air, which can negatively impact product quality, especially in industries like pharmaceuticals, food and beverage, and electronics manufacturing. Oil-free compressors ensure consistent air quality, enhancing the overall reliability of your production processes.

Improved Air Quality

One of the primary reasons businesses choose oil-free compressors is the clean, dry air they produce. In many industries, maintaining high-quality air is critical to the final product's quality and safety. Oil-free compressors, including oil-free screw compressors, provide compressed air that is free from oil contamination, ensuring that the air used in sensitive applications is pure and safe.

For example, in the food industry, using oil-free air in the packaging and processing stages helps prevent any potential contamination of products. Similarly, in the pharmaceutical industry, oil-free compressors are essential to maintaining the sterile conditions required in drug manufacturing and medical device production.

Minimal Maintenance Requirements

Another key benefit of oil-free compressors is their low maintenance needs. Without oil to change or dispose of, businesses can save time and money on routine maintenance tasks. Oil-free screw compressors, in particular, have fewer moving parts subject to wear and tear, which results in fewer repairs and longer service life.

Regular maintenance is still necessary to keep the compressor operating at peak performance, but it typically involves fewer tasks compared to oil-lubricated models.