Choosing the right Industrial Air Compressor can be a game-changer for your business, improving productivity, reducing costs, and increasing reliability. Direct Driven Air Compressor is a great choice for industries looking for an energy-efficient, low-maintenance, and reliable solution. When selecting the right compressor, consider factors such as air demand, capacity, energy efficiency, and maintenance needs.

Types of Industrial Air Compressors

Before we dive into the selection process, it's important to understand the different types of industrial air compressors available. Each type has its own set of benefits and limitations, depending on your specific requirements.

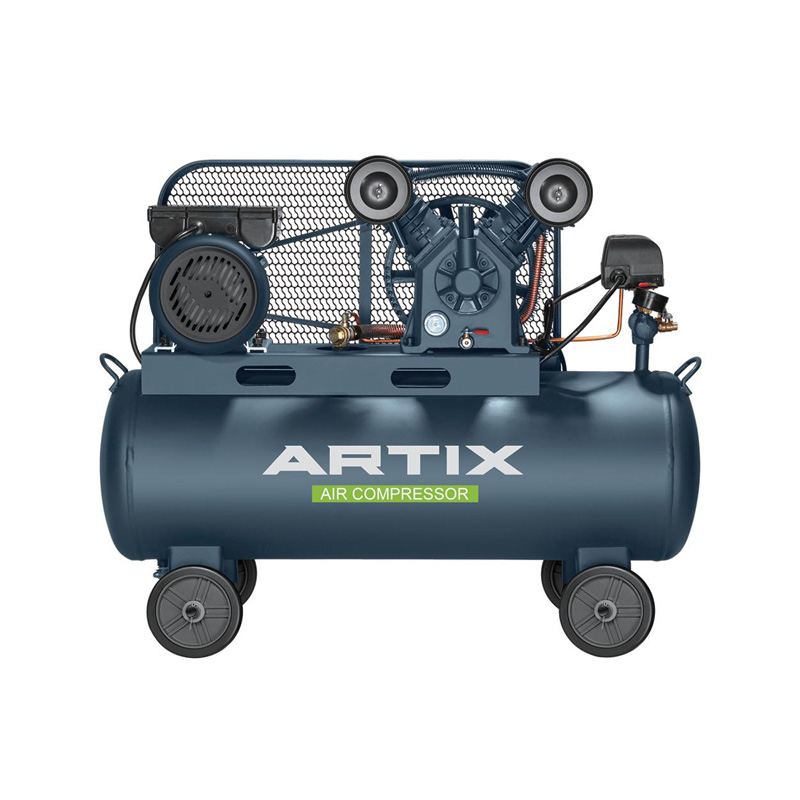

1. Piston (Reciprocating) Compressors

Piston compressors are one of the more commonly used types of compressors in industrial settings. These compressors use a piston to compress air in a cylinder and release it under high pressure. They are typically used in applications that require intermittent use and are well-suited for smaller operations.

2. Screw Compressors

Screw compressors are often used in medium to large-sized industries because they offer a more continuous, reliable air supply. These compressors use two interlocking screws to compress the air, which makes them quieter and more efficient than piston compressors. Direct Driven Air Compressors often fall into this category.

3. Centrifugal Compressors

Centrifugal compressors use a high-speed rotating impeller to increase air pressure. These compressors are typically used in very large industrial operations where high volumes of compressed air are needed continuously.

4. Scroll Compressors

Scroll compressors are commonly used in HVAC systems and refrigeration. They are highly efficient and compact, making them ideal for applications with limited space. However, they are generally used in smaller industries compared to piston or screw compressors.

Why Choose Direct Driven Air Compressors?

Direct Driven Air Compressors are becoming a popular choice for industries that require reliable, continuous air supply. Let’s break down why they may be the right option for your business:

1. Energy Efficiency

One of the main reasons Direct Driven Air Compressors are favored in industrial settings is their energy efficiency. In a direct-driven system, the motor is directly connected to the compressor, eliminating the power loss associated with belts and pulleys in traditional systems. This results in more power being transferred to the compression process, lowering energy consumption and operating costs.

2. Reduced Maintenance

Direct-driven compressors have fewer moving parts than their belt-driven counterparts. This means less wear and tear, which translates to lower maintenance costs and less frequent downtime. For businesses looking to minimize operational disruptions, a Direct Driven Air Compressor is a smart choice.

3. Higher Reliability and Durability

The direct connection between the motor and compressor means that direct-driven compressors are often more durable than other models. With fewer components that can fail, these compressors are highly reliable, ensuring continuous performance, even under high-demand conditions.

4. Compact Design

Because there are fewer parts, Direct Driven Air Compressors tend to have a more compact design. This is beneficial for businesses with limited space or those that need to install multiple compressors in a confined area. The simplicity of the design also means that these compressors are typically lighter and easier to install.

By carefully evaluating your needs and understanding the advantages of Direct Driven Air Compressors, you can make an informed decision that will help optimize your operations and keep your business running smoothly.