Whether you rely on an Industrial Oil Free Air Compressor for manufacturing processes, workshop tools, or critical plant operations, unexpected performance issues can disrupt your workflow and impact productivity. Users searching for a good brand air compressor often ask the same fundamental question: “What should I check when something goes wrong?” Understanding how to diagnose common issues can save time and minimize costly downtime.

From pressure drops to sudden shutdowns and inconsistent performance, there are several areas worth inspecting before assuming the worst. In many real-world cases, operators discover that early troubleshooting catches manageable faults before they become major failures.

1. Look at Air Intake and Filters

One of the more frequent causes of output problems — such as low air production or reduced pressure — lies at the very beginning of the air path: the intake. Over time, oil-free compressors can accumulate dust, debris, and other contaminants in their intake filters. A clogged filter restricts airflow into the compression chamber, effectively starving the machine and causing weak performance or slow air delivery. Checking and cleaning intake filters regularly is a simple initial step in diagnosing performance issues.

2. Inspect Safety and Pressure Valves

Air compressors use safety valves to relieve excessive pressure and keep operation within design limits. A malfunctioning safety valve or incorrect pressure setting may cause the compressor to behave unpredictably or shut down unexpectedly. Regularly inspecting these components helps ensure that the machine is both safe and operating at the intended pressure range.

In cases where outlets are at lower pressure than expected, it’s also wise to check for poorly functioning valves further downstream in the system — these can prevent proper pressure buildup even when the compressor itself is functioning.

3. Check for Leaks in the System

Even small air leaks can have a significant impact on performance. Compressed air that escapes through loose fittings, hose cracks, or faulty seals means that less air reaches your tools and machinery. Users often use soapy water around connections to spot leaks — bubbles form where air escapes — and then tighten or replace the affected components. Locating and fixing leaks early is one of the more cost-effective measures for restoring performance.

4. Examine Electrical Components

Power issues are another frequent source of compressor trouble. If the unit won’t start or stops during operation, the problem may stem from electrical faults such as damaged cables, loose connectors, or worn contacts on switches and relays. In industrial settings, minor wiring issues can escalate rapidly, causing repeated shutdowns or inconsistent starts. It’s important to inspect the power supply and control components carefully, and to ensure that electrical systems comply with recommended specifications.

5. Look at Cooling and Ambient Conditions

Overheating is a common struggle for many compressors running in confined or warm environments. Inefficient cooling can stem from blocked cooling fins, dusty surroundings, or inadequate ventilation. Problems like this not only diminish performance but can also trigger thermal shutdown protections in some machines. Ensuring that the compressor has space around it and that heat-dissipating parts are clean helps maintain stable performance and prevents heat-related shutdowns.

6. Wear and Mechanical Stress

In industrial applications, mechanical wear over long periods can degrade critical parts like valves, seals, and bearings. For example, hardened seals that no longer close properly may allow air to slip past, reducing pressure output. While a good brand air compressor typically includes durable parts designed for heavy use, even high-quality equipment needs periodic mechanical checks, especially after extended service.

7. When to Get Professional Help

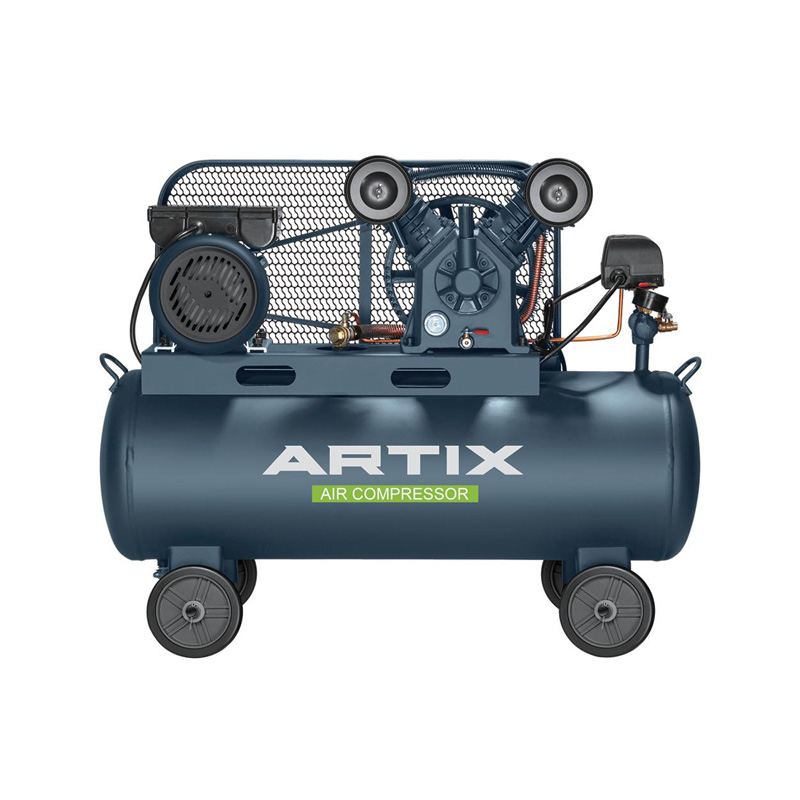

Some issues — such as internal valve damage, faulty sensors, or worn piston components — may require in-depth technical diagnostics or part replacement that goes beyond basic checks. If you’ve performed standard troubleshooting without improvement, a trained technician can provide thorough assessment and tailored solutions. Companies like Artix Machinery Co., Ltd. emphasize the value of professional maintenance services to diagnose and resolve tougher compressor challenges.

Facing trouble with an Industrial Oil Free Air Compressor doesn’t necessarily mean it’s time to replace the unit. Systematic checking of intake filters, pressure and safety valves, leaks, electrical supply, and cooling conditions often reveals manageable causes behind performance issues. By integrating regular inspections into your maintenance routine and understanding what to check when problems arise, you can keep your compressor running reliably and efficiently.

If simple checks don’t reveal the issue, don’t hesitate to engage professional support — timely intervention can help protect both your equipment and your productivity.