In industries where air purity is crucial, the choice between different types of air compressors can significantly impact the quality of the final product and operational efficiency. Among various options, oil-free air compressors, including both Belt Driven Compressor and Direct Drive Compressor models, are increasingly recognized for their ability to deliver clean, uncontaminated air suitable for sensitive applications.

An oil-free air compressor operates without the need for oil lubrication inside the compression chamber. This eliminates the risk of oil contamination in the compressed air, making it ideal for environments such as food processing, pharmaceuticals, electronics manufacturing, and healthcare. Both Belt Driven Compressor and Direct Drive Compressor designs are available in oil-free configurations, allowing users to select a lot of suitable system based on their operational requirements.

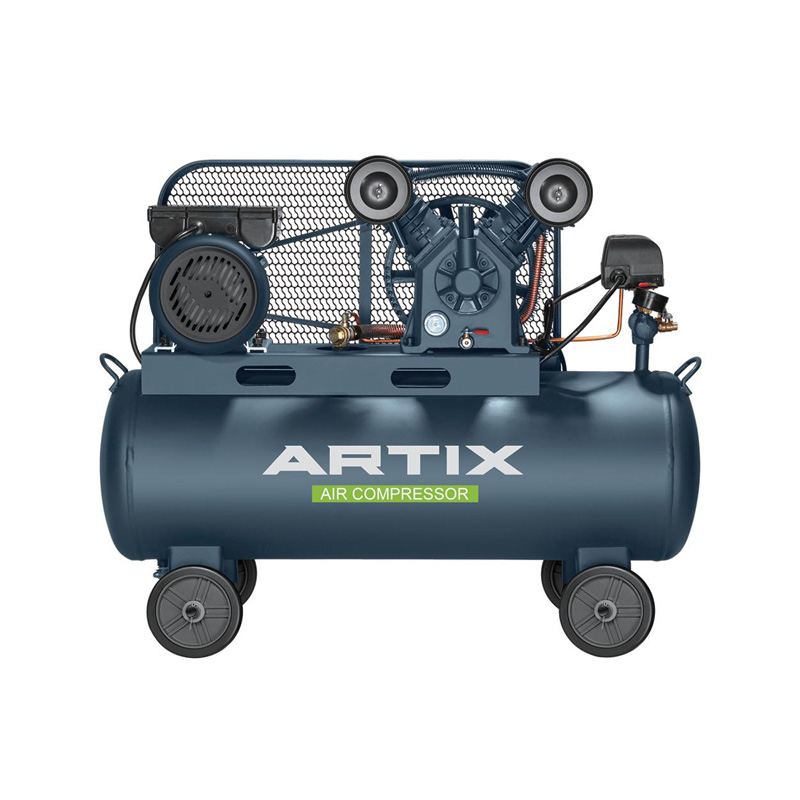

The Belt Driven Compressor, when designed as oil-free, benefits from adjustable motor speeds enabled by its belt and pulley system. This flexibility allows the compressor to adapt to varying air demand levels, providing energy savings during low-demand periods while maintaining clean air output. However, because the Belt Driven Compressor includes belts and pulleys, routine maintenance is necessary to ensure the system operates reliably without compromising air quality.

On the other hand, the Direct Drive Compressor offers a simpler design with the motor shaft directly connected to the compressor pump. This design reduces the number of moving parts and potential leak points, which can further ensure the purity of the compressed air. The direct coupling in a Direct Drive Compressor also typically results in fewer maintenance requirements and improved energy transfer efficiency, which is beneficial for continuous operation in clean air applications.

Choosing between a Belt Driven Compressor and a Direct Drive Compressor in oil-free models involves considering factors such as maintenance accessibility, operational noise, and space constraints. The Belt Driven Compressor’s ability to operate at lower speeds can reduce noise levels, which might be desirable in certain clean room environments. Conversely, the more compact footprint of the Direct Drive Compressor makes it easier to install in areas where space is limited.

Moreover, the absence of oil in the compression process reduces the environmental impact and simplifies downstream air treatment. Without oil contamination, the filtration system downstream of the compressor can be less complex and more cost-effective.

Both the Belt Driven Compressor and Direct Drive Compressor oil-free models provide reliable solutions to meet these stringent requirements. The choice often depends on the specific needs of the operation, including airflow demand, operational hours, and maintenance capabilities. Users seeking a versatile compressor that offers speed adjustments may prefer the Belt Driven Compressor, while those prioritizing simplicity and reduced maintenance might opt for the Direct Drive Compressor.

Additionally, operational efficiency plays a crucial role. The Belt Driven Compressor, with its flexible speed control, can optimize energy use during variable workloads, which can be beneficial for operations with fluctuating air demands. In contrast, the Direct Drive Compressor tends to maintain consistent performance, making it suitable for steady, high-demand environments where reliability is critical.

The oil-free air compressors are gaining traction in clean air applications because they support contaminant-free operation, lower environmental impact, and compliance with strict quality standards. Both Belt Driven Compressor and Direct Drive Compressor designs contribute unique advantages to this growing market segment. Understanding the differences and capabilities of each can help users select the right compressor to meet their clean air needs effectively.