Industrial oil free air compressors are playing an increasingly important role in industries worldwide as clean-air regulations tighten. These compressors provide an effective solution for facilities aiming to comply with stricter environmental standards while maintaining production efficiency. Alongside this, direct driven air compressors are gaining attention for their reliability and energy-saving benefits under these regulatory pressures.

1. Understanding Clean-Air Regulations Impacting Compressed Air Systems

Clean-air regulations are becoming more stringent globally to reduce industrial emissions and prevent contamination. Authorities require manufacturers to monitor and limit pollutant discharge, including oil aerosols and vapors from compressed air systems. Some key points include:

ISO 8573-1 air quality standards define classes of compressed air purity, with Class 0 being oil‑free.

Many jurisdictions mandate oil‑free air for food, pharmaceutical, and electronics production.

Environmental agencies monitor emissions, driving demand for cleaner equipment.

Now that you understand these regulations, it is clear why industrial oil-free air compressors are favored by companies committed to compliance.

2. Why Industrial Oil-Free Air Compressors Align with Regulatory Requirements

Oil‑free compressors do not use oil for lubrication in the compression chamber, eliminating the risk of oil carryover in compressed air. Benefits aligned with regulations include:

Zero risk of oil contamination in products or processes.

Simplified air quality certification due to inherently cleaner air.

Reduced environmental impact by avoiding oil disposal and leaks.

Lower maintenance complexity because no oil changes or oil filtration are needed.

Direct-driven air compressors complement these benefits by offering efficient, reliable operation that meets operational and environmental expectations.

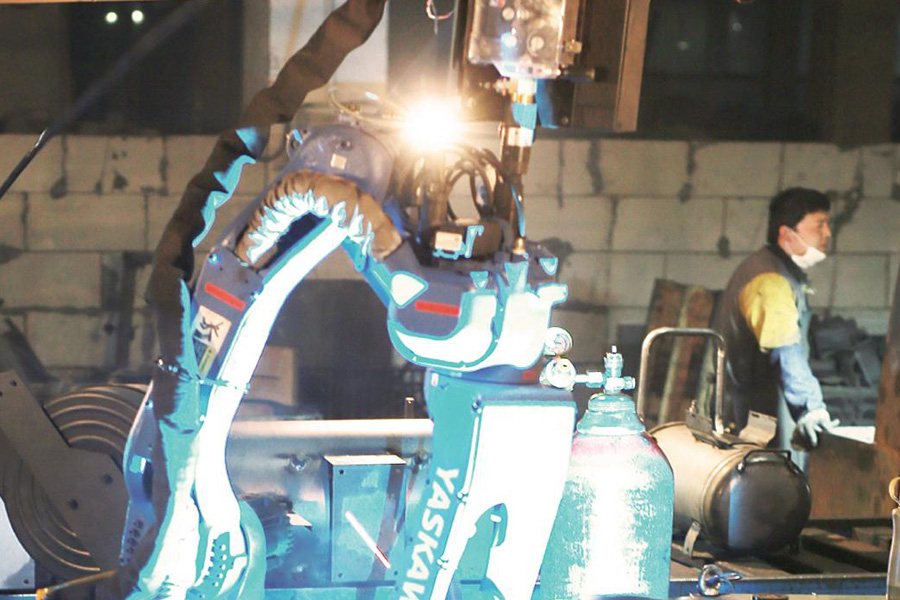

3. How Direct-Driven Air Compressors Support Regulatory Compliance

Direct-driven compressors are favored in regulated environments because:

They have fewer moving parts, reducing leakage points for oil or contaminants.

The direct motor-to-compressor coupling means no belts, pulleys, or oil-lubricated transmission components.

They tend to be more energy-efficient, lowering emissions indirectly by reducing power consumption.

Here we are going to outline specific design features that make direct-driven air compressors suitable for eco-conscious manufacturing.

4. Industries Driving Growth Amid Clean-Air Policies

Certain sectors are accelerating adoption of oil‑free, direct-drive compressors in response to environmental regulation:

Food and beverage processing: Air used in contact with consumables must meet strict hygiene and oil-free standards.

Pharmaceutical manufacturing: Clean air is critical for sterile environments and product safety.

Electronics: Even tiny oil traces can cause defects in sensitive components.

Automotive: Painting and coating lines demand oil-free air to ensure finish quality.

These sectors also benefit from direct drive compressors’ energy savings, contributing to their sustainability goals.

5. Market Trends and Future Outlook

The global market for industrial oil free air compressors is expected to grow steadily due to:

Increasing regulatory pressure worldwide.

Rising demand for energy-efficient and low-maintenance equipment.

Technological advances in direct drive designs and control systems.

Greater awareness of sustainability in manufacturing.

To learn more about market dynamics, many suppliers now offer customized solutions combining oil free and direct drive technology to help customers meet both environmental and economic targets.

6. Practical Advice for Choosing Clean-Air Compliant Compressors

For companies aiming to upgrade or expand compressed air systems under clean-air rules, consider:

Specifying compressors certified to ISO Class 0 for oil-free air.

Selecting direct driven models to reduce maintenance and improve efficiency.

Incorporating real-time air quality monitoring for regulatory reporting.

Working with manufacturers experienced in environmental compliance.

If you want assistance navigating compliance requirements or exploring equipment options, feel free to contact us for expert guidance.